Wire Mesh Screens

Donelson is proud to be the local representative for Compass Wire Screens.

Donelson is proud to be the local representative for Compass Wire Screens.

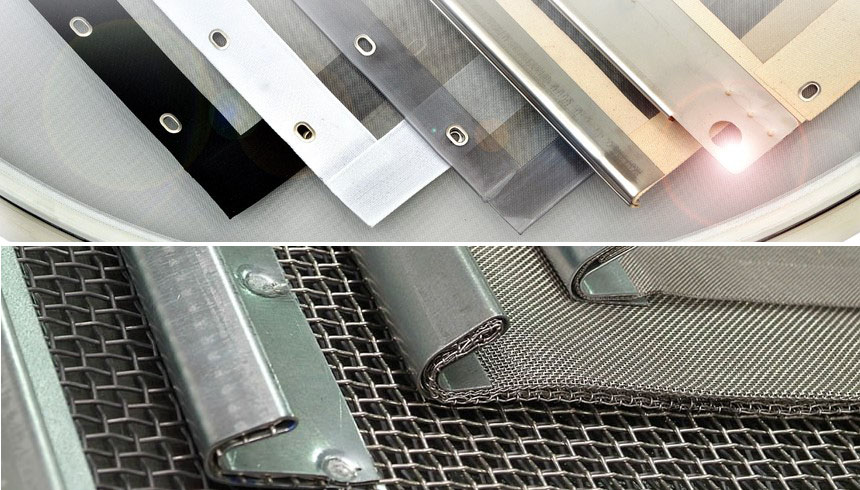

Round and pre-tension screens are produced in a temperature controlled environment to fit all OEM equipment. Years of research and development have enabled us to cultivate an effective method of even and efficient tensioning of both metal and synthetic wire cloth, either epoxied or spot welded.

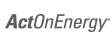

We produce replacement screens to fit all round vibratory screeners. Used to separate solids from liquids or segregate dry material into various sizes, these screens are fabricated to ensure maximum screen life through efficient product performance. Rings may be either spot welded or epoxied. Epoxies include FDA-approved and high-temperature. Spot welded rings are available for applications where epoxy is not advisable.

We produce replacement screens to fit all round vibratory screeners. Used to separate solids from liquids or segregate dry material into various sizes, these screens are fabricated to ensure maximum screen life through efficient product performance. Rings may be either spot welded or epoxied. Epoxies include FDA-approved and high-temperature. Spot welded rings are available for applications where epoxy is not advisable.

Ultrasonic screens create a secondary, ultrasonic vibration that prevents blinding on fine meshes. We can retrofit screens of any size and design with ultrasonics, and the technology is suitable for use in all vibratory screening machines. Advantages include:

- Significantly improved screening performance

- Consistent throughput and particle size distribution

- Smaller mesh sizes offer equivalent of higher throughputs

- Higher capacity utilization and improved separation effect

- Eliminates the need for mechanical cleaning while increasing the life of the screen fabric

New rings are available from stock in a variety of diameters in stainless steel. We also offer special rates to recondition your used rings.

Screens for all OEMs:

- Eriez ®

- Kason

- Midwestern Industries

- Sweco ®

- TEA (Thermal Engineering)